Dawlish Link Bridge, A379 to Secmaton Farm, Devon, UK

Devon County and Teignbridge Councils built a 26-meter bridge and 110-meter road near Dawlish, connecting…

We provide the industry’s most innovative, efficient, and greenest GRP products, tailored to meet the unique needs of your project. Here’s how we ensure that your project gains The Edge:

Mekina’s experienced team combines over 50 years of specialised experience in GRP products.

We deliver our products and services worldwide, combining global expertise with a deep understanding of how our clients bridge projects can benefit and enrich local communities.

Through the Mekina Edge, we are committed to making a meaningful difference wherever we operate.

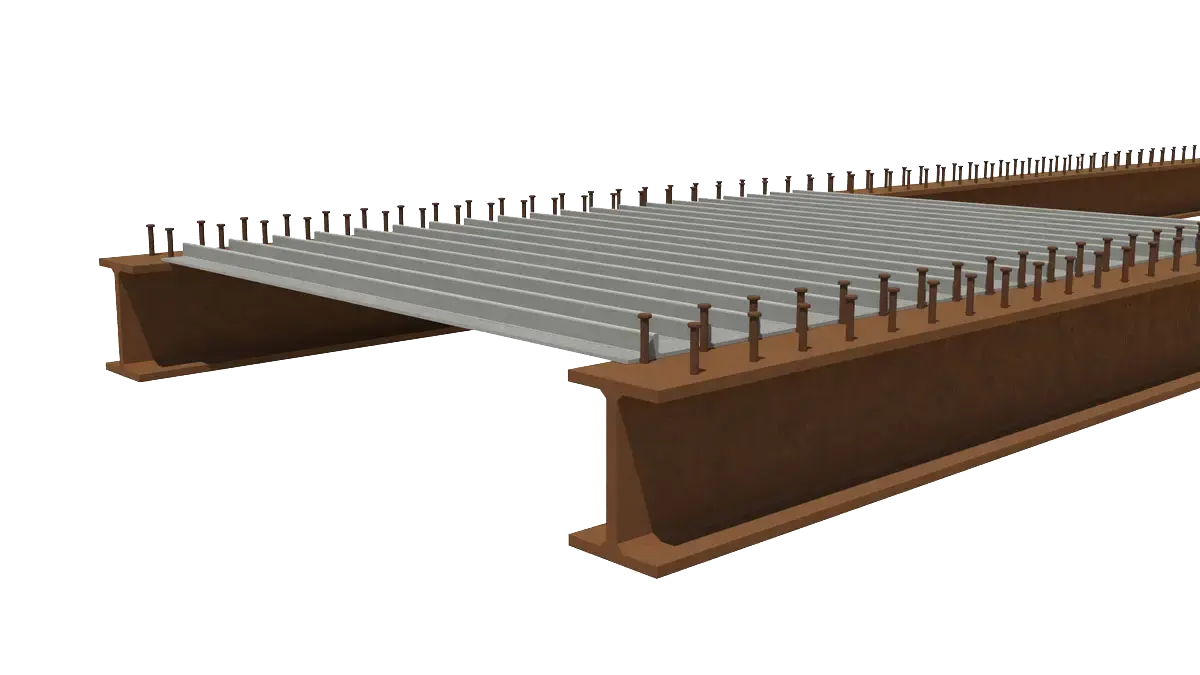

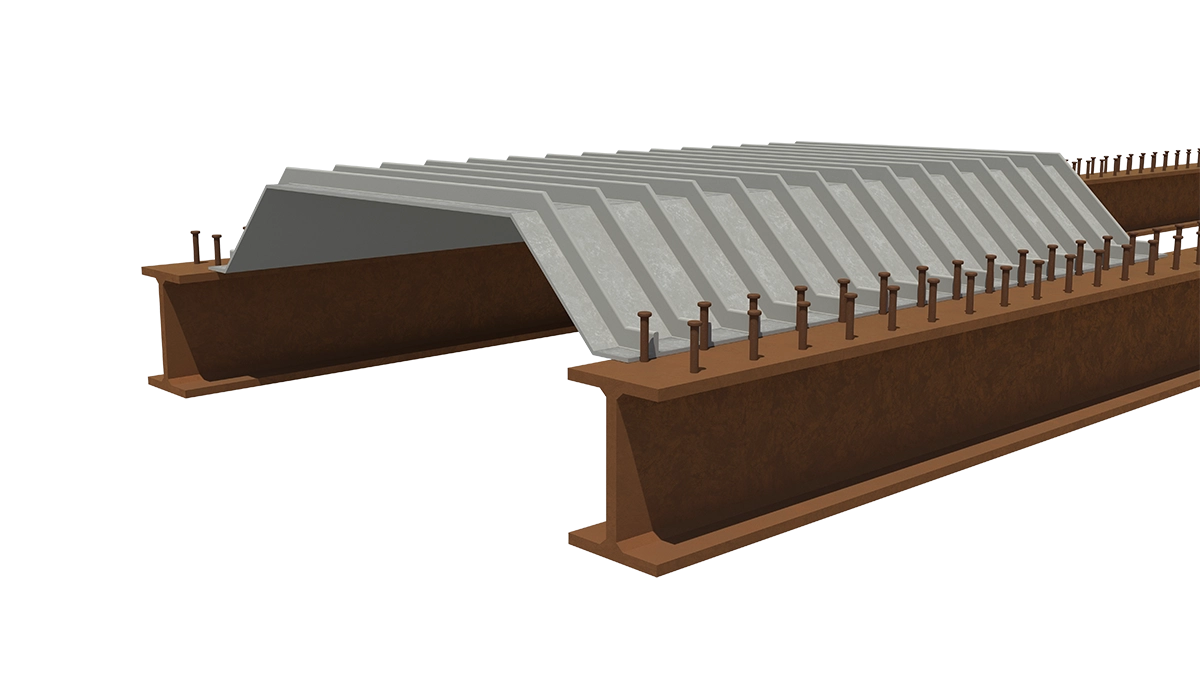

Our Glass Reinforced Polymer (GRP) panels are designed as sacrificial formwork for bridge decks, supporting concrete pours and remaining in place. Manufactured with precision, our panels ensure strength and lightweight construction, tailored for a seamless fit and efficient installation.

Mek-Dek sacrificial formwork panels are compliant with Highways CD 359 standards. Panels can be produced with integrated lifting holes for safe cranage and handling.

Choose Mek-Dek for formwork solutions that combine cutting-edge engineering, sustainable practices, and unmatched technical support. Our GRP panels bring innovation, safety, and cost-effectiveness to your infrastructure projects, ensuring a durable, reliable solution tailored to your needs.

Mek-Dek panels are suitable for a range of infrastructure projects including:

Find out how our market-leading GRP Permanent Formwork products are reshaping the industry.

Devon County and Teignbridge Councils built a 26-meter bridge and 110-meter road near Dawlish, connecting…

A new overbridge on a busy Buckinghamshire road was built as part of the HS2…

Mekina Industries partnered with Daracon Group to replace Martinsville's Owens Road Bridge, using durable, eco-friendly…

Due to space constraints near a listed road bridge, Mekina Industries' GRP formwork panels were…